| New ceramic technologies and novel multifunctional ceramic devices and structures | |

|---|---|

| Research Area | FP7-PEOPLE-2013-ITN Marie Curie Action: 'Initial Training Networks' |

| Project Reference | PITN-GA-2013-606878-CERMAT2 |

| Coordinator | Professor Andrea PICCOLROAZ |

| Project Funding | 2571865 EURO |

| Project Web-page | http://cermat2.unitn.it/ |

| AU Leader | Professor Gennady S. Mishuris |

| Contract Type | Initial Training Networks (ITN) |

| Start Date | 2013-11-01 |

| Duration | 48 months |

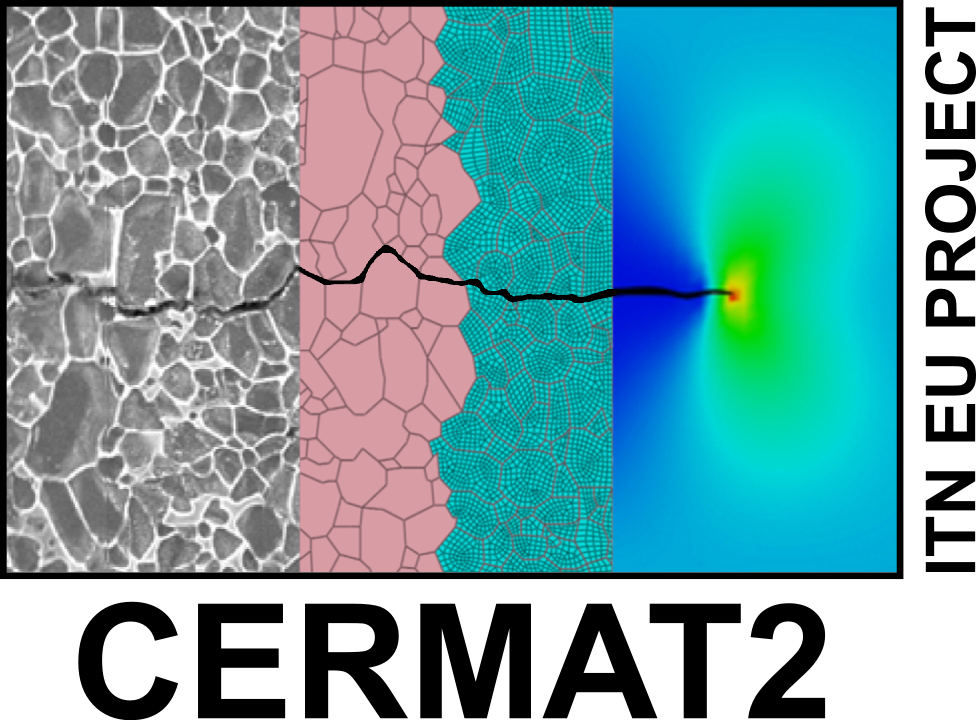

| Project Description | The CERMAT2 project is aimed to train young researchers in understanding the modelling of Solid Mechanics problems applied to the process and design of advanced ceramics in a synergic collaboration between academia and industry, in view of social developments related to enhancement of industrial production and pollution reduction. In the EU, the ceramic industry is employing about 200,000 people and involves a production (including bricks, sanitaryware, tiles, technical ceramics, and refractory products) on the order of € 28 billion per year. Industries related to the production of traditional ceramics are well developed in Italy (with a € 9 billion turnover), while advanced ceramics are targeted in Germany and UK (a sector with a 20% growth per year). Advanced ceramics find special (biomedical, thermomechanical or nanotech) applications, where they exhibit unchallenged characteristics (for instance, thermal stability, wear resistance and chemical inertia) and, compared to other finishing materials, can minimize environmental impact. Despite the technical and industrial interest, the production of ceramic components is based on poorly understood empirical processes, often difficult to control. As a consequence, the production of rejected items can still be strongly reduced, a target having an impact on both cost reduction and environment preservation. In fact, the employed technologies involve a massive waste of energy and material, so that even a small increase in the mechanical performance of the ceramic structure would yield a reduction in weight of articles with a deep impact on pollution reduction. The optimization of the production process is directly linked to the modelling of the behaviour of powders and binders used during compaction, in the simulation of sintering, and in the design of mechanical characteristics of the final pieces. |

Contact Details

Institute of Mathematics and PhysicsAberystwyth University

Physical Sciences Building

Aberystwyth

Ceredigion

SY23 3BZ

Tel: 01970 622 808 Fax: 01970 622 826 Email: imaps@aber.ac.uk